Production intelligence for 3D printing filament manufacturers

Real-time visibility, automated quality control, and complete traceability — all in one clean system built specifically for 3D printing filament production

See acqSYS in Action

Real product screenshots from our production intelligence platform in use

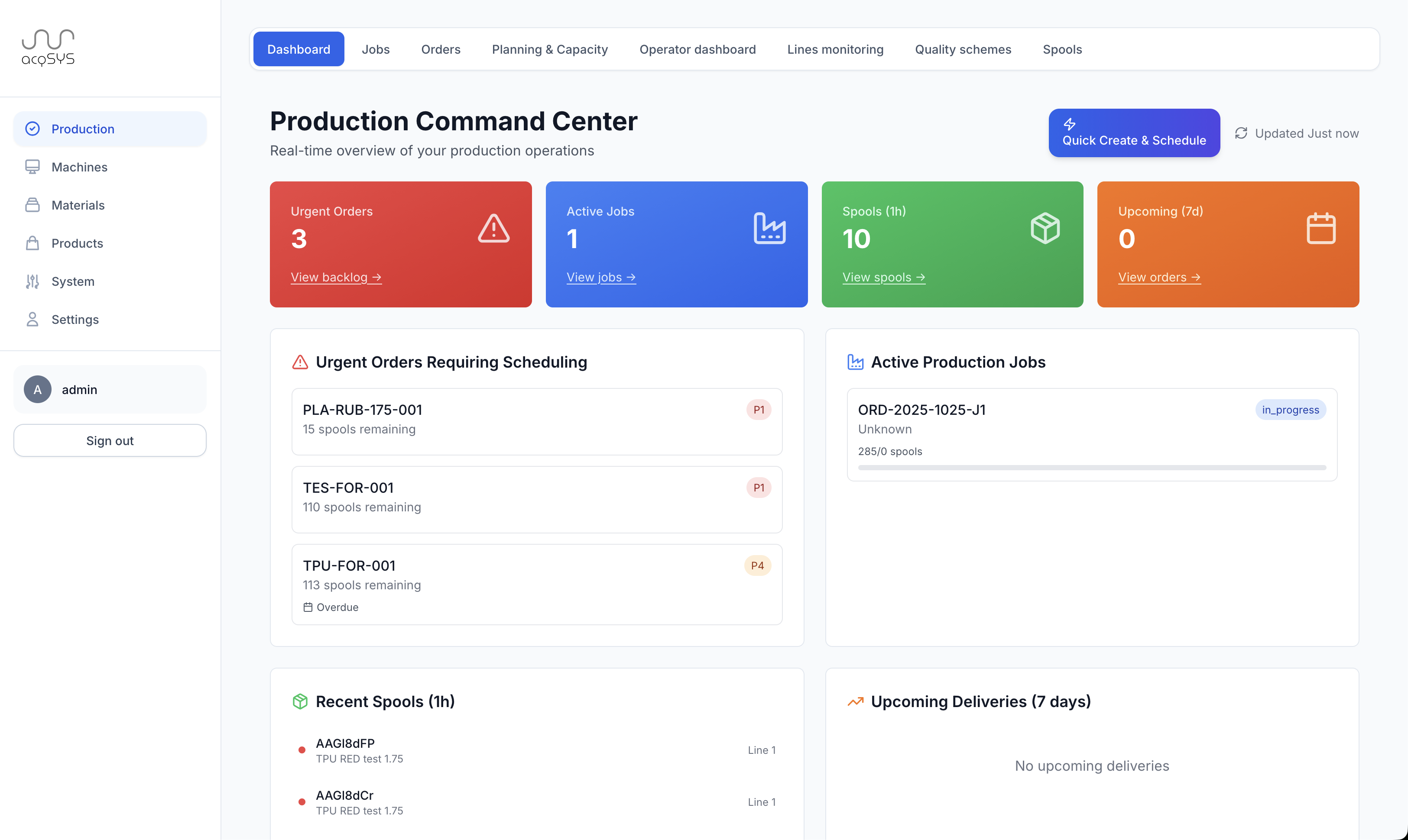

Production Command Center

Real-time overview of all production operations, active jobs, urgent orders, and recent spools. Monitor your entire shop floor at a glance.

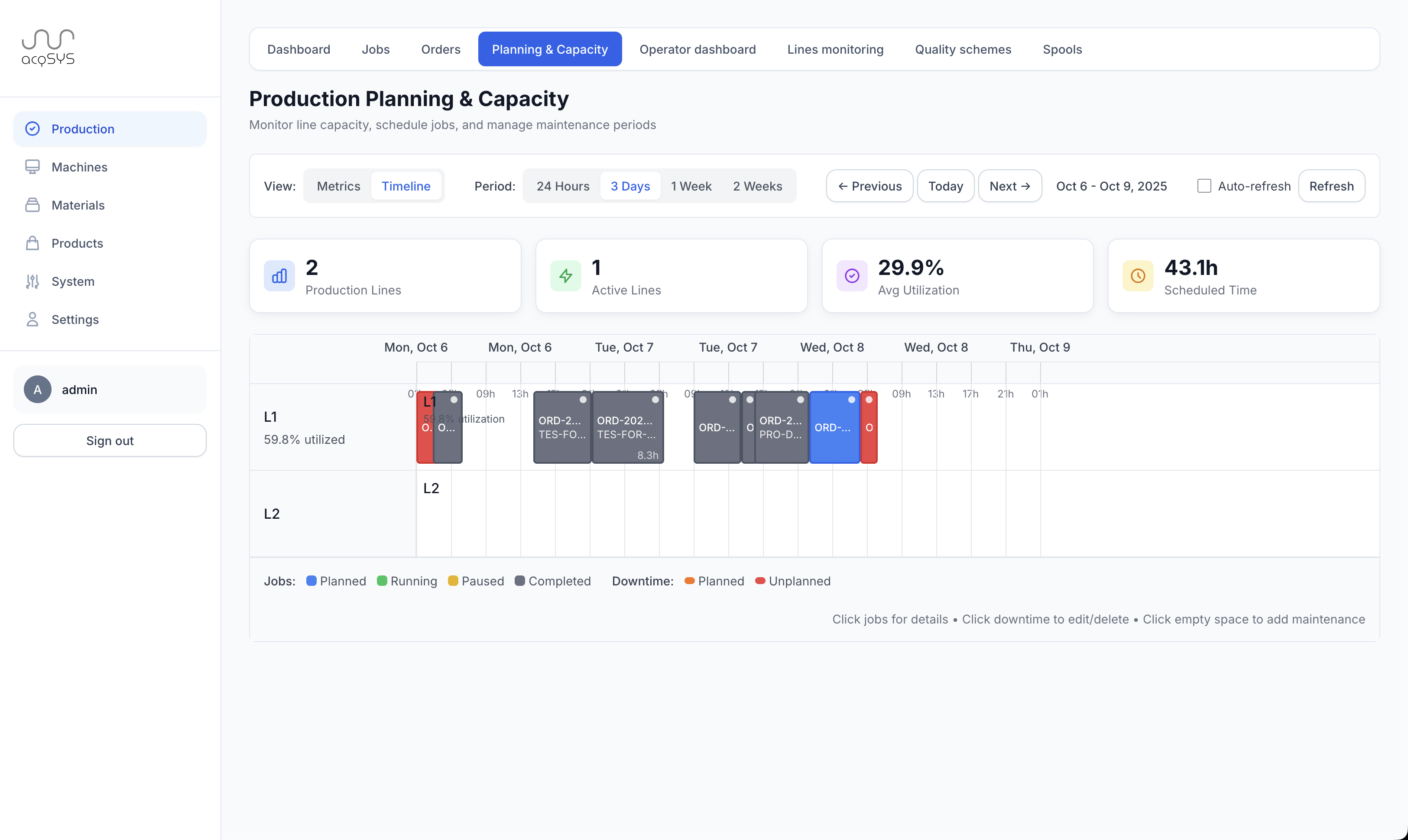

Planning & Capacity Management

Visual timeline for scheduling jobs across production lines. Monitor capacity utilization and identify bottlenecks before they impact delivery.

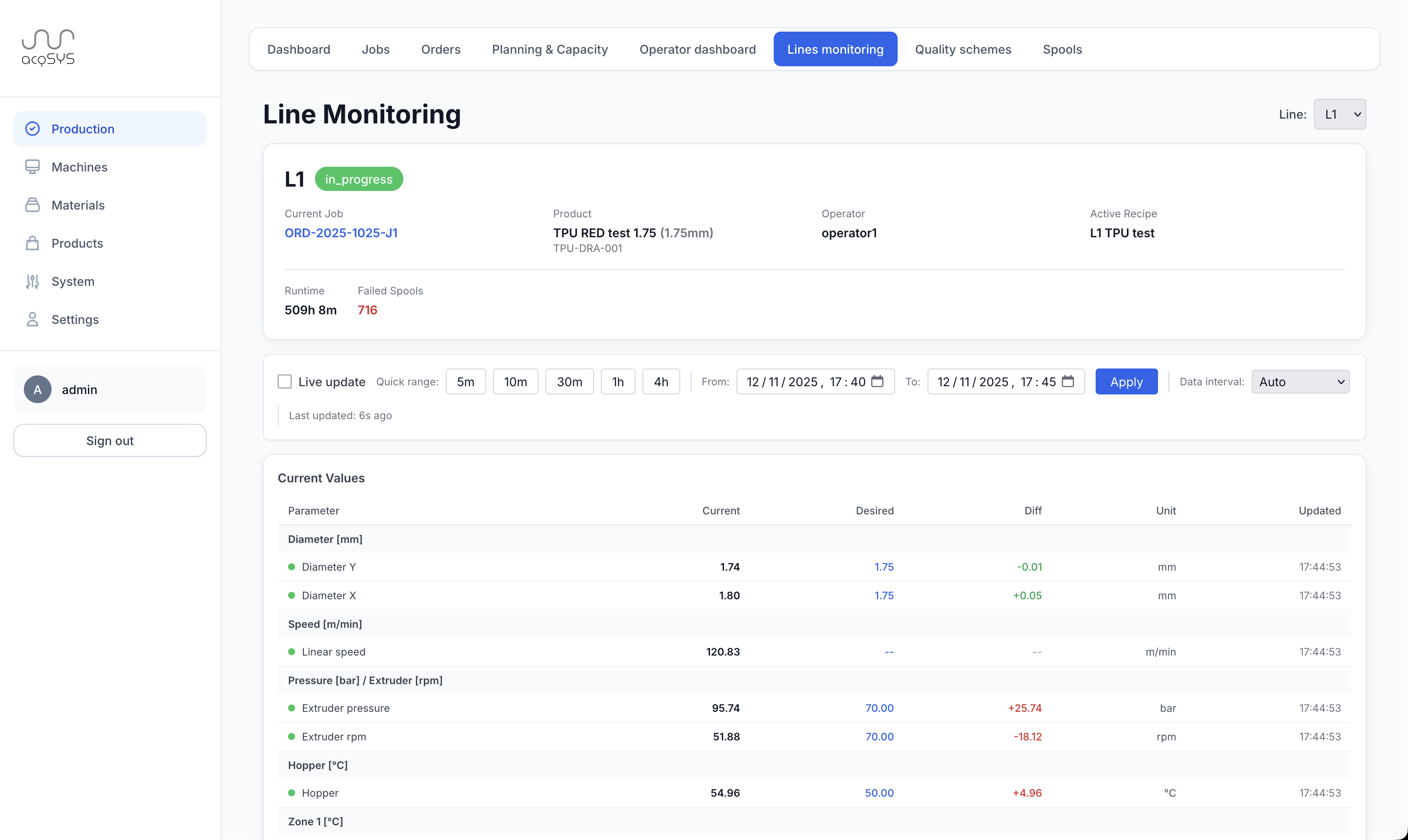

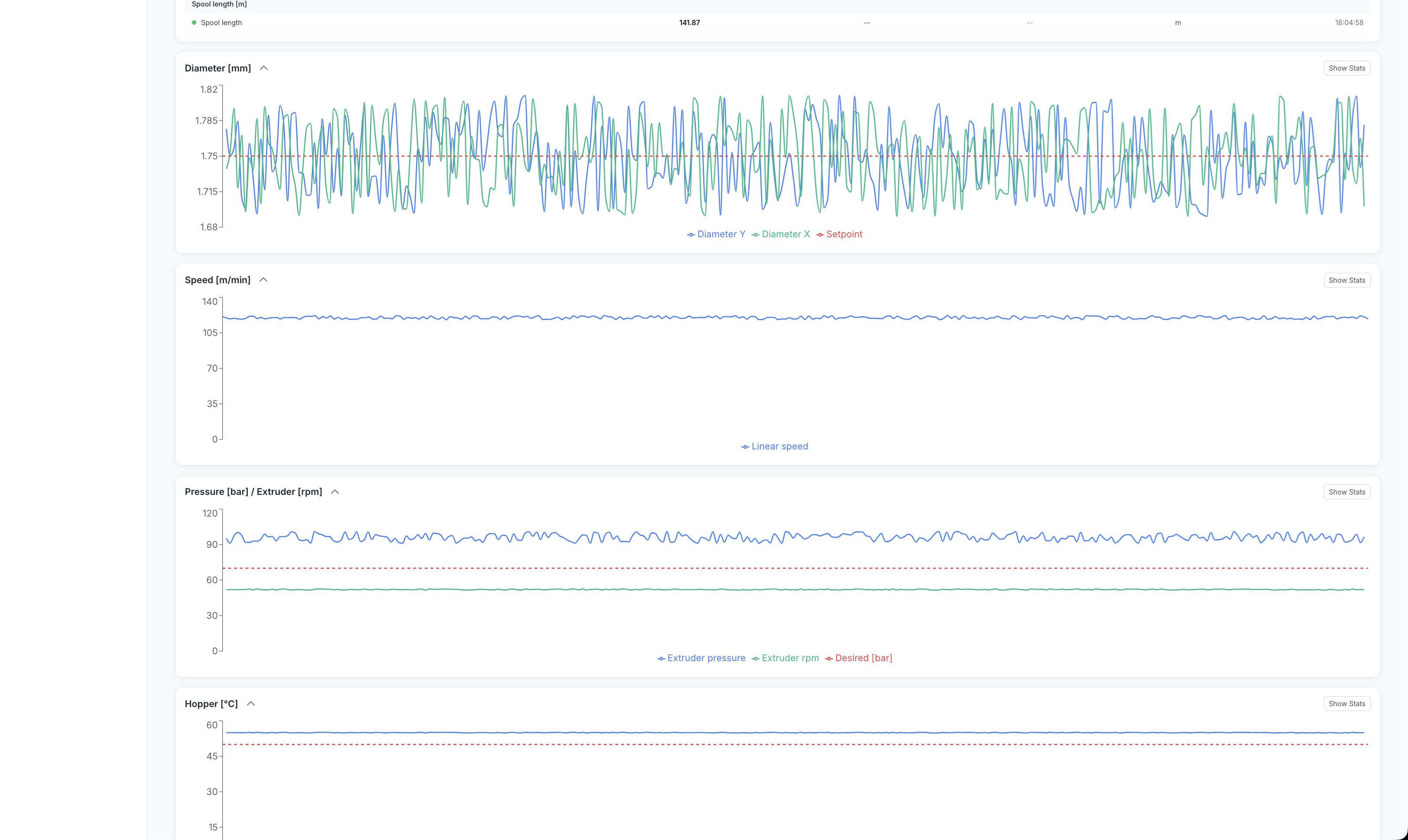

Real-Time Line Monitoring

Live telemetry from your production lines. Track diameter, speed, temperature, and pressure in real-time with instant deviation alerts.

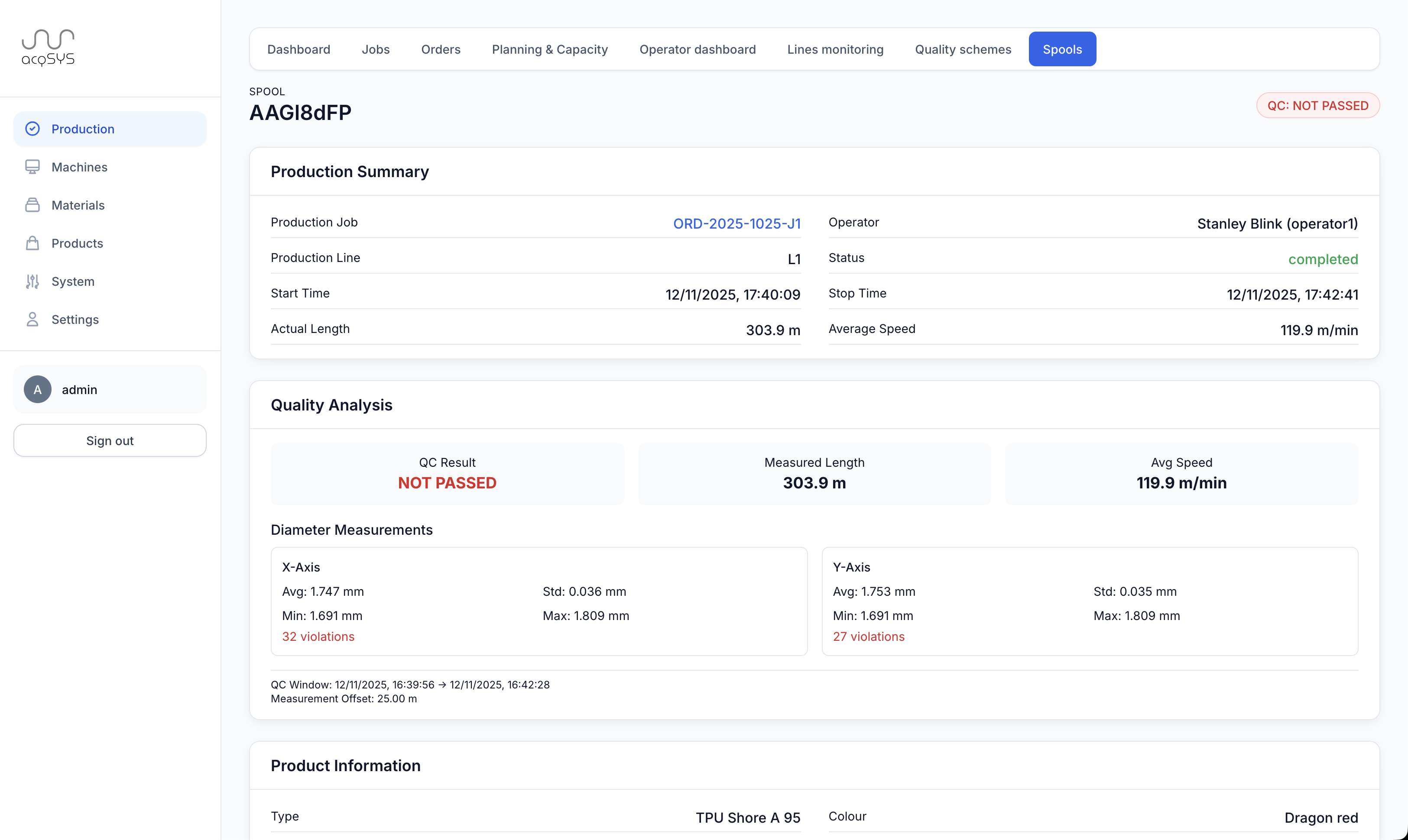

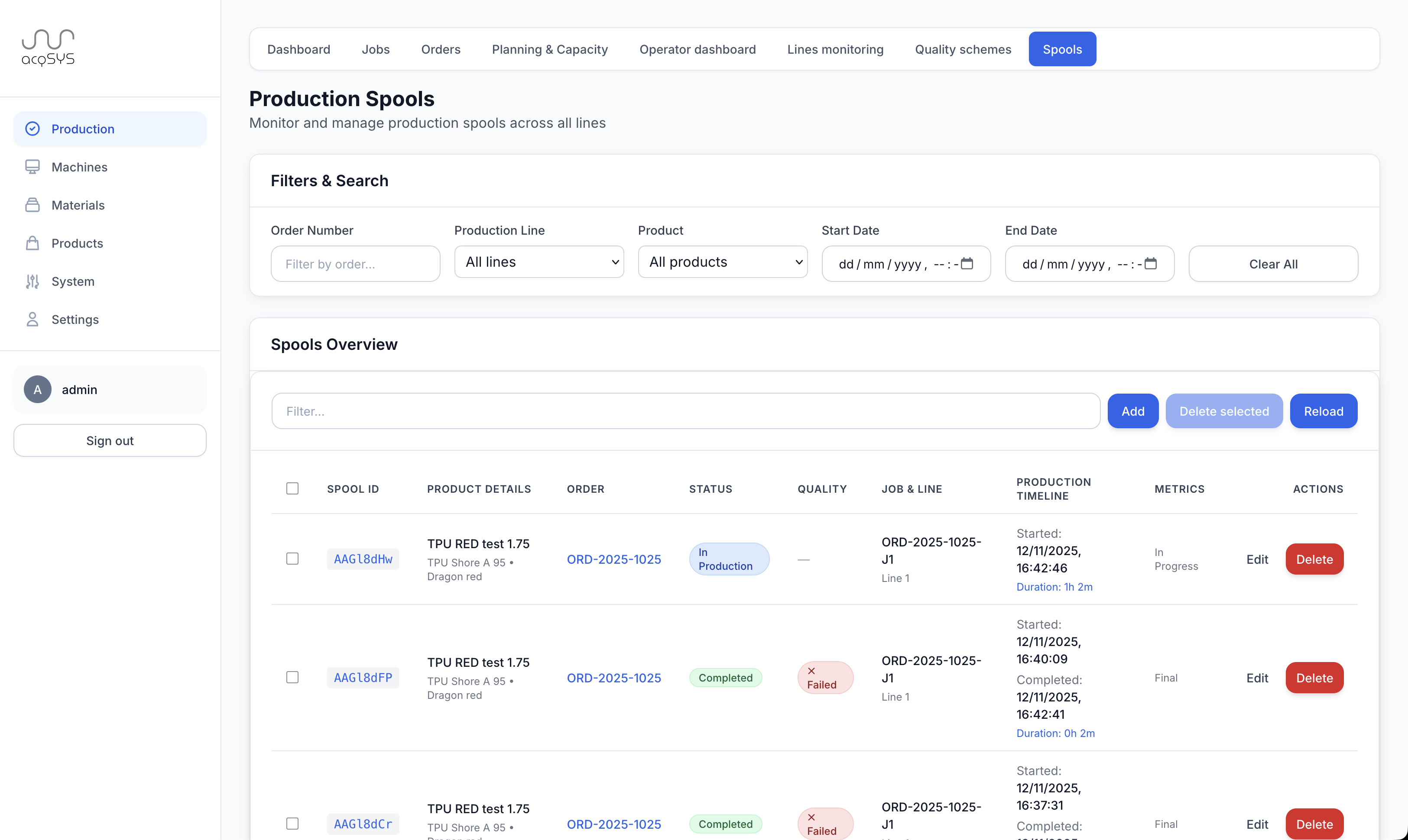

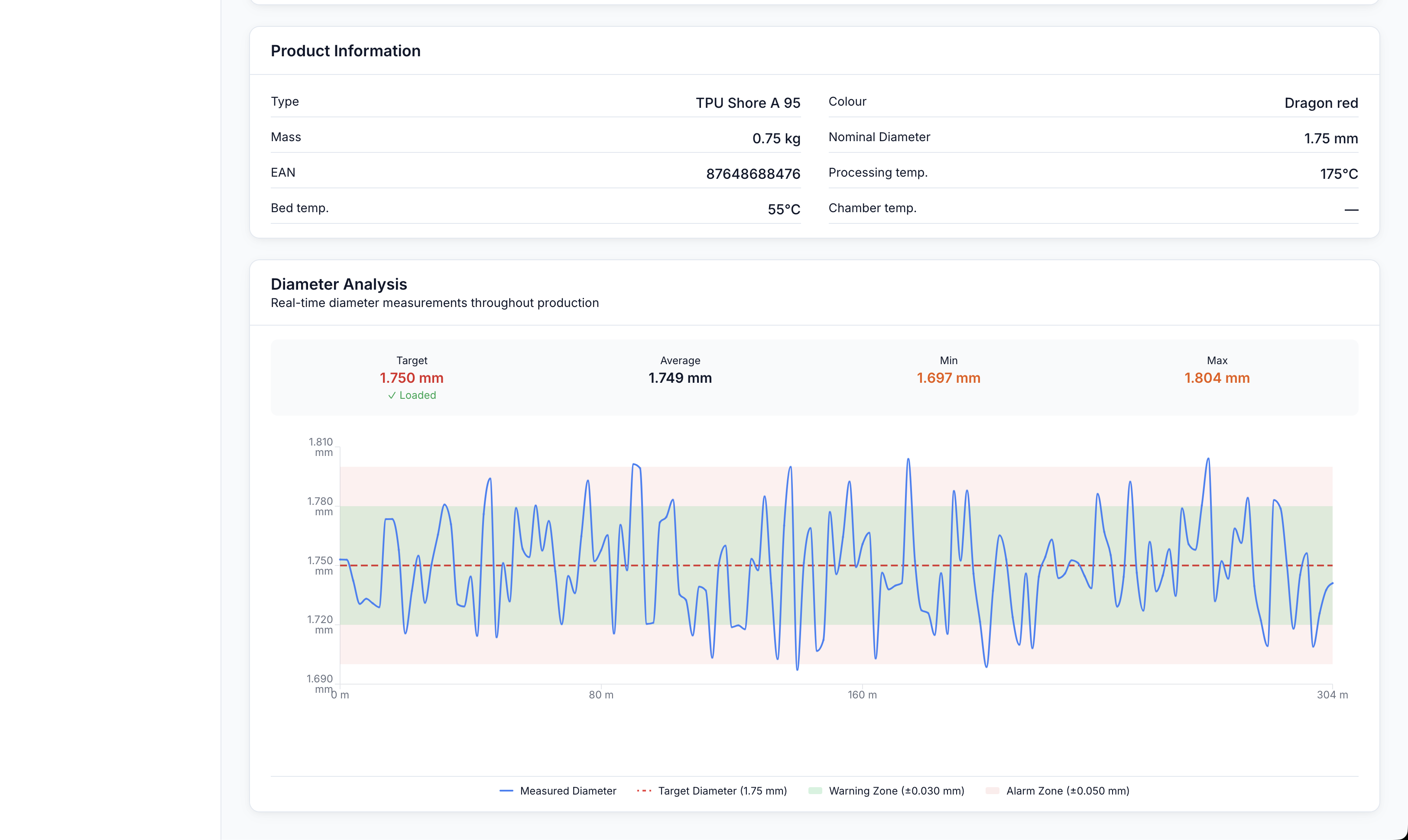

Complete Traceability

Full genealogy for every spool with production data, quality measurements, and real-time diameter analysis throughout the entire production run.

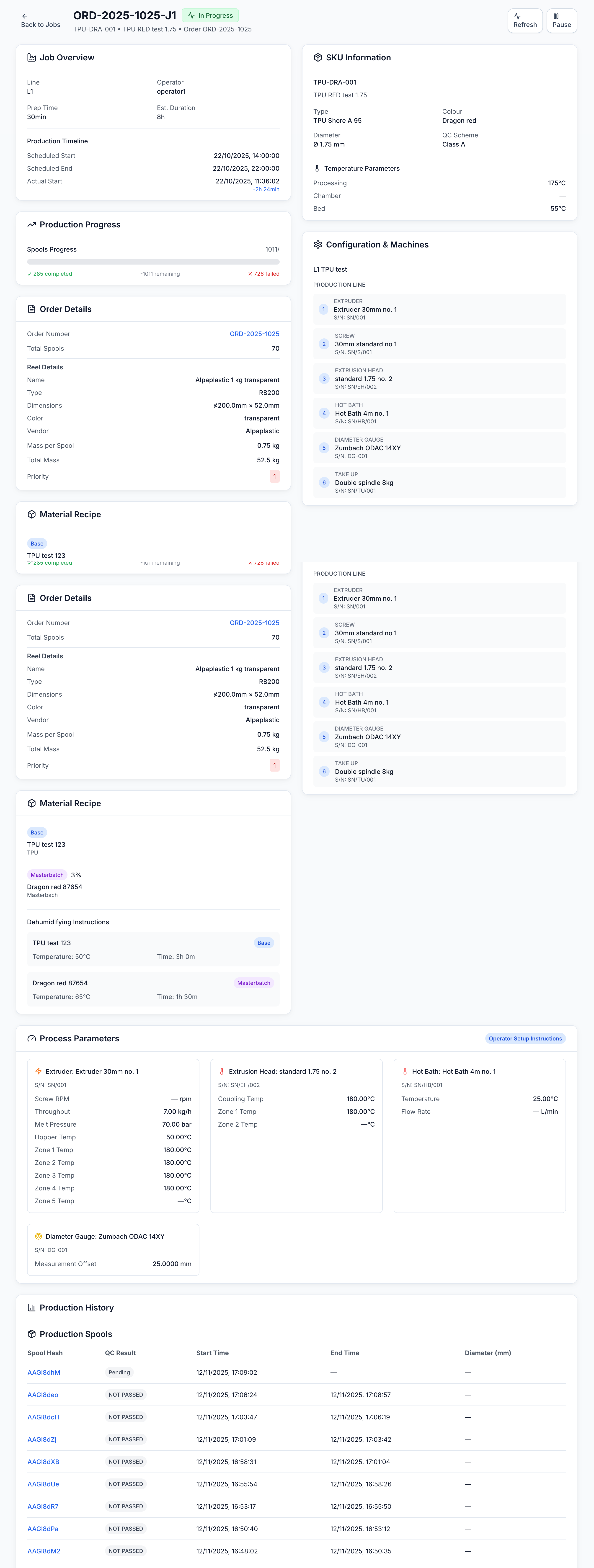

Digital Documentation

Complete digital job sheets with all production data: job overview, SKU specs, order details, material recipes with formulations, process parameters for all machines, and production history. No more paper on the shop floor. Hover to scroll through the document.

Comprehensive Feature Set

Every tool you need to run an efficient, quality-focused filament production operation

📈 Real-Time Telemetry

Live data streams from production lines showing diameter (X/Y), linear speed, extruder pressure and RPM, hopper temperature, and more. Historical trends with configurable time ranges for in-depth analysis.

📦 Spool Management

Monitor and manage all production spools across lines. Filter by order, product, date range, and production status. Complete production timeline and quality metrics for each spool.

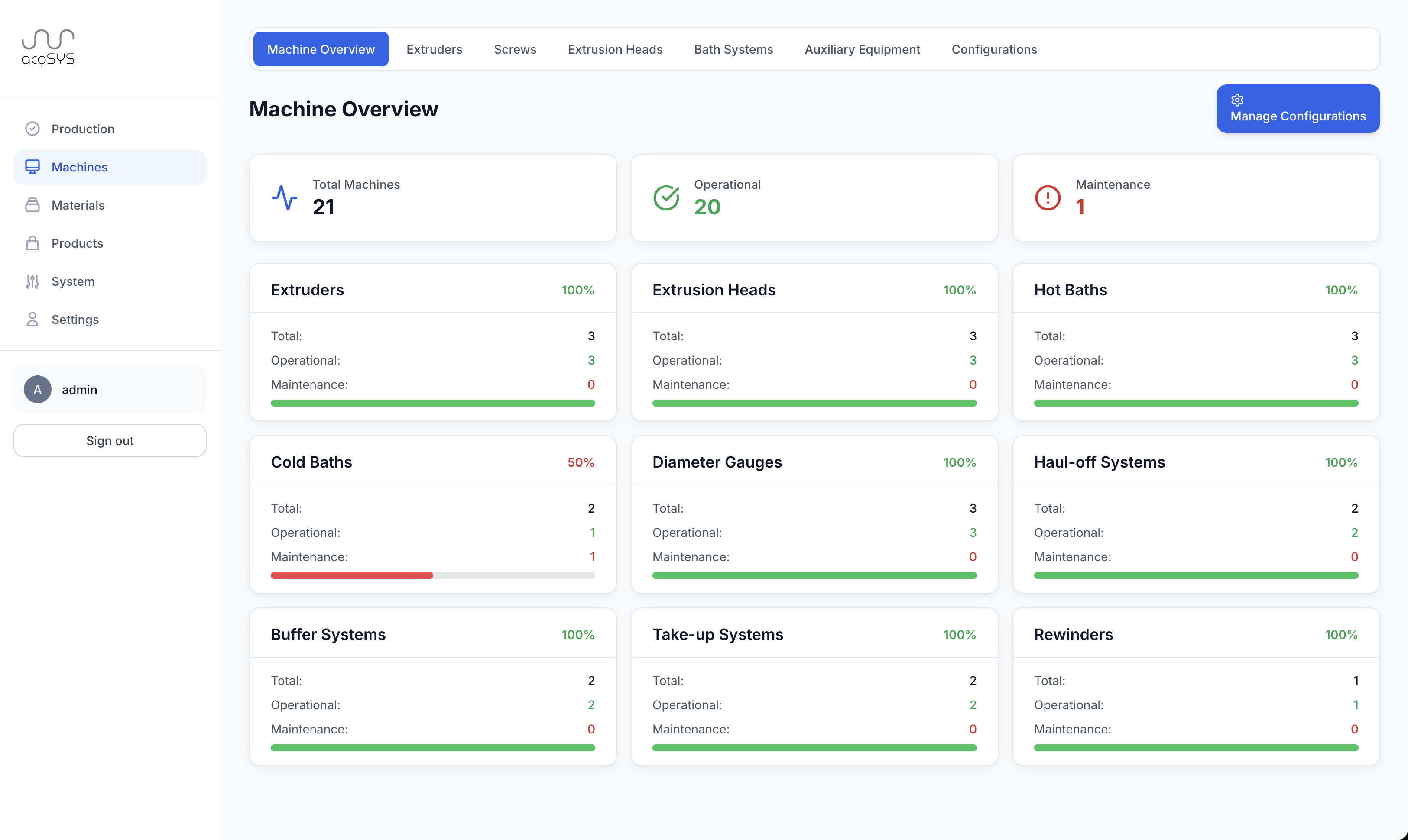

⚙️ Machine Management

Track operational status of all equipment: extruders, extrusion heads, bath systems, diameter gauges, haul-off systems, rewinders, and more. Real-time maintenance alerts.

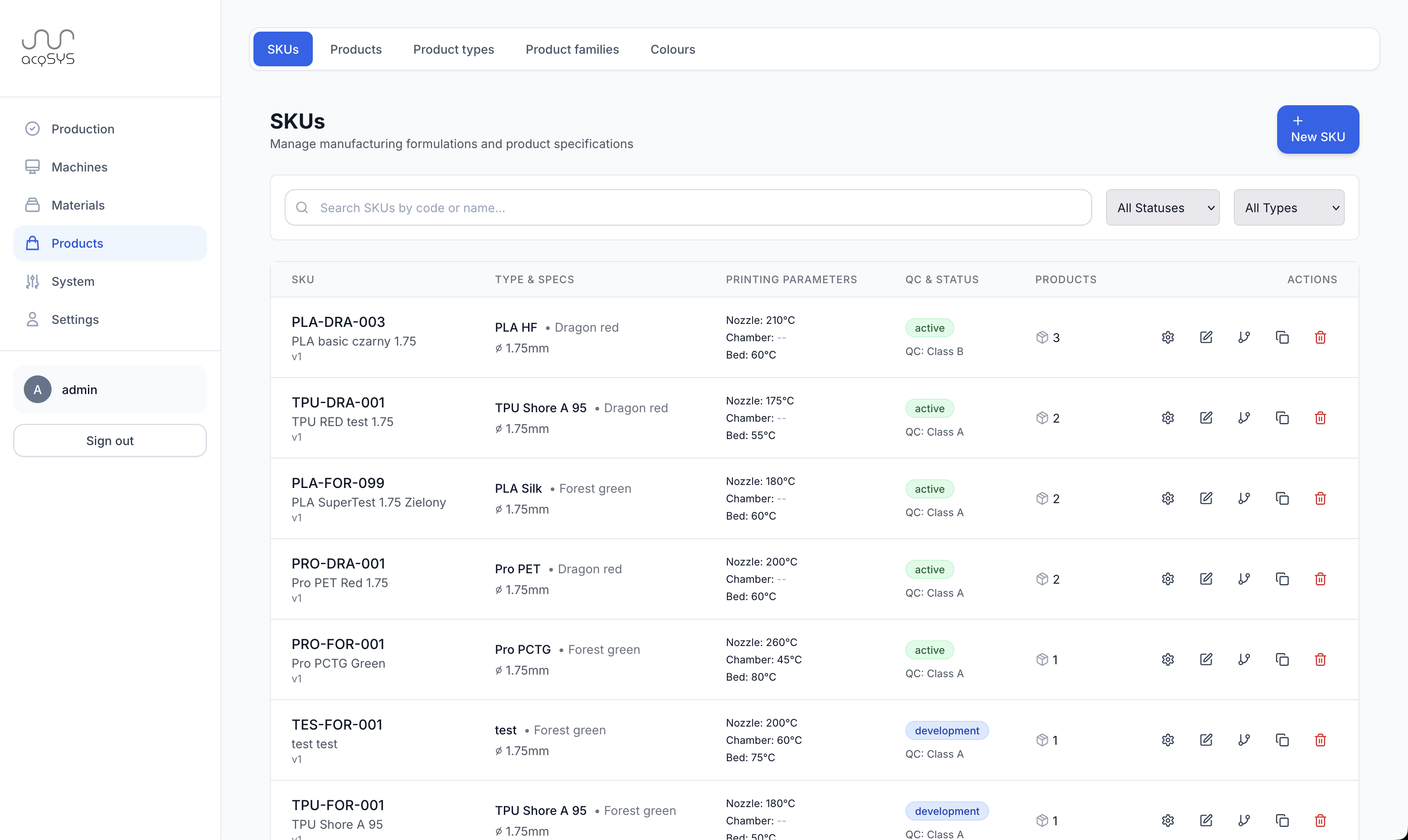

🏷️ Product & SKU Management

Manage manufacturing formulations and product specifications. Define printing parameters, QC standards, and material compositions for every product variant.

📊 Quality Analytics

Real-time quality analysis with diameter measurements throughout production. Statistical process control with warning and alarm zones for immediate quality deviations.

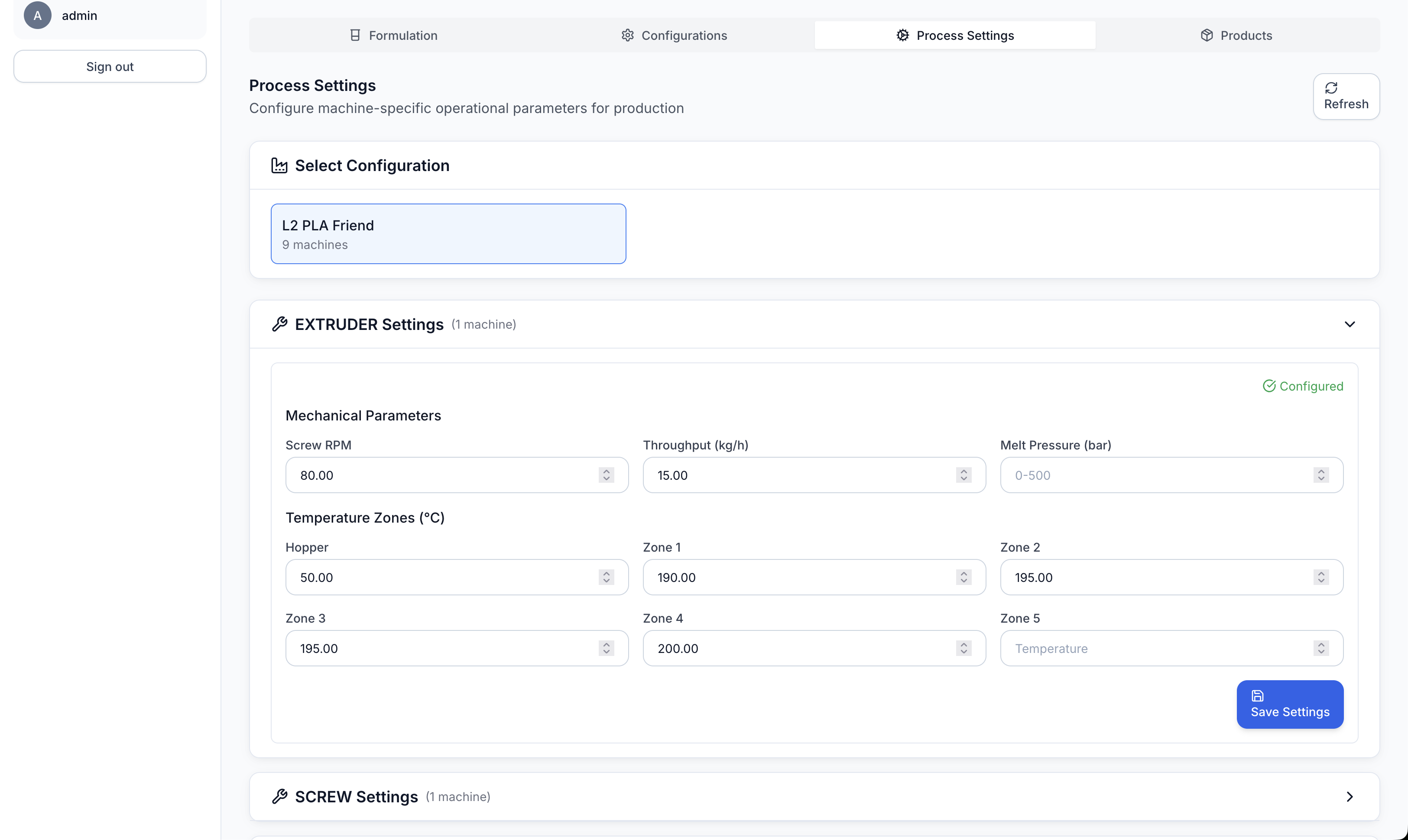

⚡ Process Configuration

Configure machine-specific operational parameters. Define temperature zones, screw settings, throughput targets, and pressure parameters for optimal production.

Everything you need for intelligent manufacturing

Complete production intelligence platform built specifically for 3D printing filament manufacturers

Real-time Telemetry

Connect extruders, haul-offs, winders and QC sensors via OPC UA, Modbus, MQTT and more. Live dashboards with alerts keep teams ahead of drifts and downtime.

Planning & OEE

Schedule jobs, balance lines and measure OEE automatically. Turn bottlenecks into throughput.

Traceability & QA

Full genealogy for lots, spools and reels. Specs, test results and deviations tied to each unit. QR codes link production history to every spool.

Customer Spool Portal

Give your customers transparency. Each spool gets a unique QR code for tracking batch info, test results, and certificates.

Digital Documentation

Store production recipes, process instructions and material databases in the cloud. Updated in real-time, accessible from any browser or smartphone.

Inventory & Materials

Raw material database, batch tracking, and machine park management. Track material preparation from receipt to production.

Alarms & Notifications

Thresholds and trend rules trigger alerts on speed, diameter, ovality, temperature and more — to email or chat.

Open API & Integrations

REST + webhooks for ERP, LIMS and MES. Multi-protocol support (OPC UA, Modbus TCP, MQTT, Profinet, EtherCAT). Your data remains yours.

Ready to transform your filament production?

See acqSYS in action. Tell us about your production process and we'll tailor a demo to your needs.